Automatic pellet fired automatic hot water space heating boiler with automatic clearing of burner and igniter that offers as high as 92% efficiency.

Efficiency:

90,6 – 93,6%

Output:

11 – 41 kW

Hopper :

installed on one side

| SmartFire leaflet |

Product Description

SmartFire pellet fired boiler features with compact design. Most components are installed inside, behind the casing that protects against harmful external factors and mechanical damages. Inside SmartFire boiler there are two main assemblies: the body and fuel supply system.

Boiler body consists of: manifold, steel heat exchanger, combustion chamber and ash pan chamber. The steel heat exchanger includes vertical flue tubes and deflector. The heat exchanger is fitted with manual cleaning system. The heat exchanger seats on the lower part of boiler body that includes combustion chamber, ash pan chamber and exhaust manifold. The burner is installed inside combustion chamber. The burner is fitted with automatic cleaning system. The fuel is supplied to the burner from above thanks to gravitation, using the screw feeder. Directly under the combustion chamber the ash-pan chamber is located where ash pan is installed to collect ash from the burner.

The second main assembly of the boiler relates to fuel supply system that is the integral part of fuel dispenser which comprises the part of boiler external casing. It consists of: fuel dispenser, fuel screw feeder along with the motoreducer. Fuel is fed from the dispenser with screw feeder that feeds the fuel to the burner inside the combustion chamber. Boiler body is coupled with feeding system thanks to flanged screw feeder. The front wall of SmartFire boiler is provided with two masking grilles. Under the left masking grille there is access door that ensures access to the combustion chamber and ash-pan chamber. Under the right masking grille there is the access opening for the lower part of fuel supply system and the controller. Above the right masking grille, on the front wall the display is installed that provides the user with information on boiler current status, operating parameters and allows boiler setup.

Heating water inlet and outlet purposed for boiler connection to the central heating system is located on boiler rear wall and is provided with internal threaded G1L” stub pipe. The rear wall of boiler is provided also with exhaust breeching that discharges exhaust gases to the chimney. The rear wall of boiler is provided with exhaust fan. Over the breeching there is exhaust temperature sensor. The controller controls volume of the air supplied by the fan.

The outer casing and boiler body are insulated with mineral wool that protects against heat loss during boiler operation. Boiler casing is provided with high quality powder-coated steel slabs.

Temperature thermostat

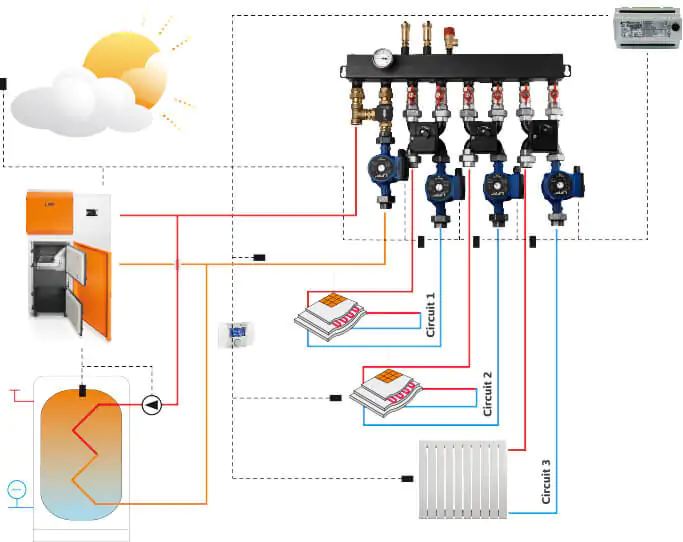

An advanced controller controls the operation of the boiler and boiler room system including pumps, valves, actuators, buffers and the boiler. This way all the devices make for an integrated system to ensure optimal performance.

Pneumatic pellet transport and storage system

An advanced controller controls the operation of the boiler and boiler room system including pumps, valves, actuators, buffers and the boiler. This way all the devices make for an integrated system to ensure optimal performance.

Boiler sectional drawing:

Sectional drawing is for reference only and may differ from actual boiler construction.

Specification

| Material | Steel |

| Feeder | Screw feeder, valve |

| Burner | Burner, automatic ignition, automatic cleaning |

| Controller | Output control, temperature thermostat, 2 heating circuits (+2 circuits optionally), 1 hot water circuit, lambda probe (optionally), Internet Wi-Fi (optionally), remote control (optionally) |

| Heat exchanger cleaning | Manual lever / automatic system (optionally) |

| Fuel | Pellets |

| Efficiency | 90,6 - 93,6 % |

| Hydraulics kit (optionally) | Kit includes energy efficient pump and thermostatic valve |

| Dispenser volume | 150 / 240 / 440 L |

| Fuel supply system | Screw feeder, rotary valve; optionally: additional pneumatic supply system or screw feeder of higher performance |

| Output | 11, 15, 17, 22, 31, 41 kW |